Now more than ever, consumers demand convenience and adaptability in their always-on connected lifestyles. Not having to carry around extra charging cables or repeatedly buy replacements for the car is a convenience consumers are willing to pay for.

Wireless charging first appeared in vehicles in 2011 when Powermat integrated its technology into the Chevrolet Volt. Today, Powermat’s wireless charging technology can be found in over 8 million vehicles worldwide

In-car wireless charging is becoming a standard feature of the modern driving experience and the automotive industry must continuously adapt to rising power demands from smartphones, including changes in mobile device power specifications, demand for greater freedom of positioning, and increased use of proprietary and private charging protocols.

These changes require particular attention to design from Tier 1 suppliers and manufacturers. Thermal build-up caused by wireless charging system inefficiencies and challenges related to in-cabin environments are nothing new. Overheating can cause device batteries to degrade at a faster rate and slows down charging speed, which negatively impacts the user charging experience.

Thermal analysis of the transmitter (in-cabin wireless charger) and receiver (mobile handset) systems can be, to some extent, conducted separately to better understand and resolve thermal challenges. However, there is still coupling between the two systems – one system’s dissipated heat is reflected as a rise in the other’s ambient temperature. Both the transmitter and receiver systems typically use some form of thermal shutdown or throttling mechanisms to prevent overheating.

Analyzing the Behavior of Mobile Handsets

For mobile handsets, these mechanisms limit operation to relatively low temperatures. While the exact temperature threshold is vendor and model-dependent, most phones will shut down charging operations if internal phone temperature rises above 37-40°C. Given this, mobile handset protection mechanisms are the dominant factor in determining the overall charging rate and whether the system goes into thermal protection mode.

The three primary strategies typically employed to prevent overheating in leading handsets are as follows:

- Regular charging: The device will send an end of charge signal once the maximum temperature threshold is reached.

- Throttled charging: The device will reduce the charging rate when its internal temperature crosses a certain threshold.

- Fast charge switching: Similar to throttled charging, the device will reduce the charging rate when its internal temperature crosses a certain threshold but also requires a change in protocol from fast to standard charging and may require an internal drop-in voltage capacity.

Let’s take a closer look at how these strategies affect thermal management and power performance in the transmitter and receiver, and how it’s possible to optimize their relationship for in-vehicle applications.

Optimizing Mobile Handset Charging Profiles for In-Vehicle Wireless Chargers

There are relatively few options to optimize the transmitter in line with Qi standards, as they are most often designed to comply with industry standards, meaning they are interoperable with multi-vendor device receivers. They can also be designed to communicate exclusively with private or proprietary charging protocols.

Support for Private and Proprietary Fast Charging Protocols in In-Vehicle Applications

Private and proprietary fast-charging protocols enable faster and higher power wireless charging for mobile devices in specific nominal conditions. Support for fast charging protocols also improves efficiencies and reduces thermal build-up.

Optimizing Receiver Placement in In-Vehicle Applications

Another way to optimize heat losses from the transmitter is to ensure maximum spatial freedom, meaning devices can still charge and receive power without optimal docking or placement. This can be achieved by selecting the correct tray size, or by sending a notification via the transmitter to inform the user of the need for realignment.

Optimizing Receiver Charging Profile

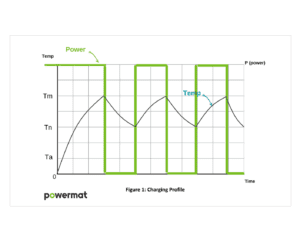

One way for the transmitter to exercise greater control is by completely shutting down the power transfer when the receiver overheats and resuming once the device temperature cools down. According to Powermat’s analysis, an optimal power profile for embedded mobile handsets is one that enables an equilibrium point for the maximum allowed charging. No on and off switching algorithm can provide higher charging speeds than this strategy.

An optimized charging profile is key

Thermal behavior depends largely on the receiver design, in-vehicle temperature, and placement misalignment for standard transmitter and receiver systems. There are multiple strategies for optimizing heat management and power performance via adjustments to the transmitter and receiver, as well as placement offsets. Reaching extreme conditions that impact battery performance is not advised; therefore, Powermat solutions do not employ “normal charging” or “throttled charging.” Instead, our technology has been developed to achieve a more optimized charging profile when complemented with the strategies discussed above.